Additional knowledge on Shipbuilding: Shipbuilding Knowledge A-Z

Before going through this article, we should know about the three core principles that originated these terms – ( Ship IMO Type 1, 2, 3).

- IMO Ship Types are used for Product/Chemical Tanker Classification.

- The suitable type based on the Intended Products/Chemical Substance carried by the vessel.

- IMO Type used for standardized the configuration of “Tank Construction & Pollution Control“

1st – What is Product/ Chemical Tanker?

Chemical tankers are cargo ships constructed or adapted and used for the carriage of any liquid chemicals in bulk. Chemical tankers are required to comply with the various safety aspects detailed in Part B of SOLAS Chapter VIII but are additionally required to comply with the mandatory International Bulk Chemical Code (IBC Code).

As well as industrial chemicals and clean petroleum products, such ships also often carry other types of sensitive cargo which require a high standard of tank cleanings, such as palm oil, vegetable oils, tallow, caustic soda, and methanol.

Oceangoing chemical tankers ranging from 5,000 to 59,000 DWT in size, which is smaller than the average size of other tanker types due to the specialized nature of their cargo and the size restrictions of the port terminals where they call to load and discharge.

Chemical tankers normally have a series of separate cargo tanks that are either coated with specialized coatings such as phenolic epoxy or zinc paint or made from stainless steel. The coating or cargo tank material determines what types of cargo a particular tank can carry: stainless steel tanks are required for aggressive acid cargoes such as sulfuric and phosphoric acid, while ‘easier’ cargoes — such as vegetable oil — can be carried in epoxy coated tanks.

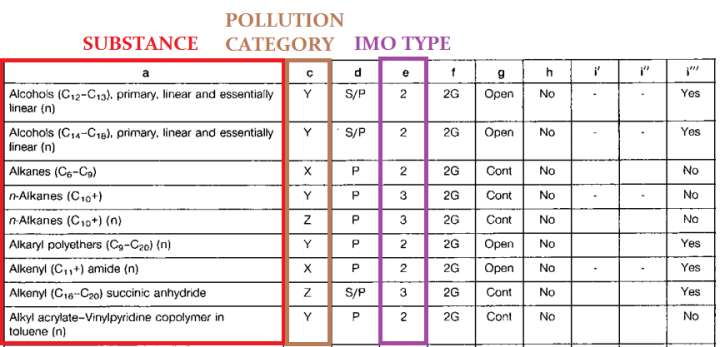

2nd – How many types of Chemical substances that designing type of vessel?

Chemical cargoes can be very dangerous, most of them being flammable and/or toxic, some of them extremely so. The IBC Code defines three ship types (ST) of chemical tankers: ST1, ST2, and ST3.

-ST1 is a chemical tanker intended to transport most dangerous products, which require maximum preventive measures to preclude an escape of such cargo. Accordingly, a type 1 ship should survive the most severe standard of damage stability and its cargo tanks should be located at the maximum prescribed distance onboard from the shell plating.

-ST2 is a chemical tanker intended to transport products requiring significant preventive measures.

-ST3 is a chemical tanker intended to transport products requiring a moderate degree of containment to increase survival capability in a damaged condition.

The IBC Code lists, in its fourteen chapters, the requirements that must be satisfied by a ship prior to it being certified as a chemical tanker regardless of the specific cargoes it is intended to carry. Within each chapter, the designer is given an option of the level of compliance required. In compliance with the more onerous requirements is chosen, the ship will be more sophisticated and will, therefore, be able to carry the more hazardous cargoes.

Chapter 15 of the Code contains ‘Special Requirements’ which are cargo-specific and which must be complied with only if that specific cargo is to be carried. Chapter 16 addresses aspects, which are the responsibility of the operator, whilst Chapter 17 lists all chemicals considered being suitable for transportation by sea.

Note: (Existing ship type 3 chemical tankers will no longer be allowed to carry vegetable oils HOWEVER, Ship Type 3 vessels be allowed to carry vegetable oils providing they have double bottom and satisfy the operational double sides criteria – Regulation 4.1.3 of MARPOL Annex II)

3rd – How IMO ship type affects on Cargo Tank Construction and Pollution Control

***Tank capacity limitation:

ST 1 : The quantity of cargo required to be carried in ship < 1,250 m3 in any one tank

ST 2 : The quantity of cargo required to be carried in ship < 3,000 m3 in any one tank

ST 3 : There is no filling restriction for chemicals assigned to Ship Type 3 Cargo Tank

***Tank location:

Cargo tanks shall be located at the following distances inboard – MEAN OF DOUBLE BOTTOM HEIGHT TO THE BASE LINE OR MOULDED LINE (ABOVE THE BOTTOM PLATE).

ST 1 : from the side shell plating, not less than the transverse extent of damage (B/5 or 11.5m whichever is less), and from the moulded line of the bottom shell plating at centerline, not less than the vertical extent of damage (B/15 or 6 m whichever is less), and nowhere less than 760 mm from the shell plating. This requirement does not apply to the tanks for diluted slops arising from tank washing.

ST 2 : from the moulded line of the bottom shell plating at the centerline, not less than the vertical extent of damage ( B/15 or 6m whichever is less), and nowhere less than 760 mm from the shell plating. This requirement does not apply to the tanks for diluted slops arising from tank washing.

ST 3 : no requirement

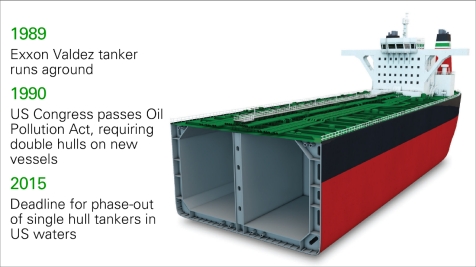

Single hull tanker will no more apply in US water from 2015.

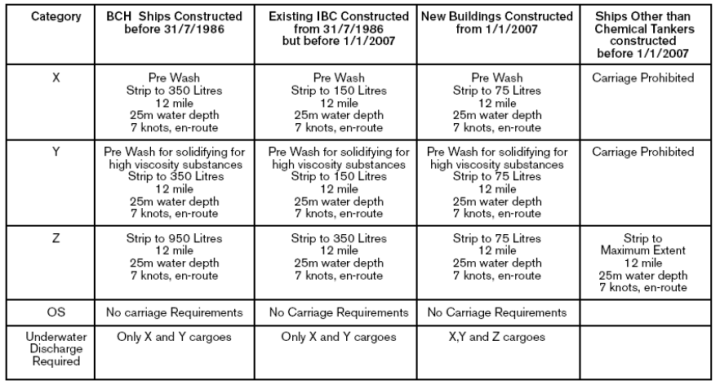

***Cargo Pollution Control:

Base on the substance pollution category type X, Y, Z. The suitable Stripping/Discharge arrangement will comply accordingly. See the below table:

Note: In any case, no discharge of residues containing noxious substances is permitted within 12 miles of the nearest land.

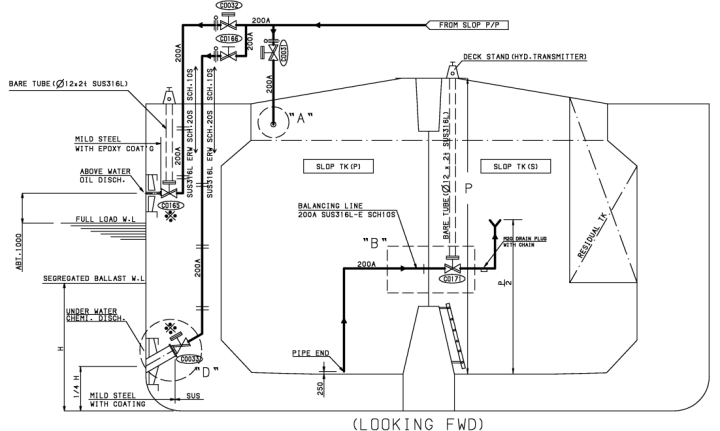

Example of Underwater chemical discharge arrangement on the chemical tanker.

Do you want to learn more about Shipbuilding knowledge from Basic design through Supervision?

There are a lot of topics from contruction to inspection and basic theory, Click Shipbuilding Knowledge

Thank you. Never see something clear until this post.

LikeLiked by 1 person

Hope you enjoy the knowledge.

LikeLike

Good job bro! very easy to understand the concepts imo on chemical tankers

LikeLiked by 1 person

I’m from Korea, thanks to the unique information found on the internet.

LikeLike

Thanks

LikeLike

Hope you enjoy the knowledge

LikeLike

A very good information page . Easy to understand for Mariners who survived successfully and didn’t know they were doing great job and service to humanity till they stopped sailing and sat infront of computer

LikeLike