This topic is an additional knowledge support for SHIP STRENGTH CALCULATION (Part 1) and SHIP STRENGTH CALCULATION (Part 2).

Under sea-going condition, the Hogging and Sagging condition make the ship steel be continuously compressed and stretched those making steel become fatigue collapsed specially at amid ship area as general.

Giving that the longitudinal stress which can cause the ship to break up. The stress is resisted by all continuous longitudinal members those placed far further from Neutral axis of the cross-section area. Ex: Double bottom ( Keel plate, center girder, longi-member, bilge plate .. ), Main strength deck ( deck stringer plate, longi-girder..), Side shell ( upper part – as called Sheer Strake ).

HOLD YOUR HORSE

Do you want to learn more about Shipbuilding knowledge from Basic design through Supervision?

There are a lot of topics are waiting for your adventure, Click Shipbuilding Knowledge

Strake

To understand what strake is, we need to again understand the construction of shell plating.

In naval architecture and ship construction, each of these plate has an identification. These are numbered in a certain pattern. For example, the plates on the side shell plating are numbered like this.

So in the above example, we have A-Strake, B-Strake and so on.

If we want to be more specific, We can say that we have starboard A-Strake , starboard B-strake and so on. Similar naming will be on the port side.

Sheer Strake

As defined, Sheer strake is the topmost strake of the Side shell plating.

Sheer strake is usually of higher thickness and strength than other strakes. This is because this strake can resist lot of physical damages during the life of ship.

Because of its important role on the ship, the Class rule also has a particular requirement those needed the high attentions and serious concerns as below – captured from ABS/ BV rule:

- The width of the sheer strake is to be not less than 1.2m (example for ship L = 100m)

- The fillet weld at the connection of the welded sheer strake and deck plate may be either full penetration or deep penetration (back-gouging) weld.

- The upper edge of the welded sheer strake is to be rounded smooth and free of notches.

- Where guard rails are provided, the upper edge of sheer strake is to be kept as low as possible. – Part B – BV rule

- In general, the distance between two adjacent butts in the same strake of shell or deck plating is to be greater than two frame spaces. – Part B – BV rule

If the shear strake is rounded, its radius, in mm, is to be not less than 17t, where t is the net thickness, in mm, of the sheer strake.

Longitudinal seam welds of rounded sheer strake are to be located outside the bent area at a distance not less than 5 times the maximum net thicknesses of the sheer strake.

- Fixtures such as bulwarks, eye plates are not to be directly welded on the upper edge of sheer strake, except in fore and aft parts.

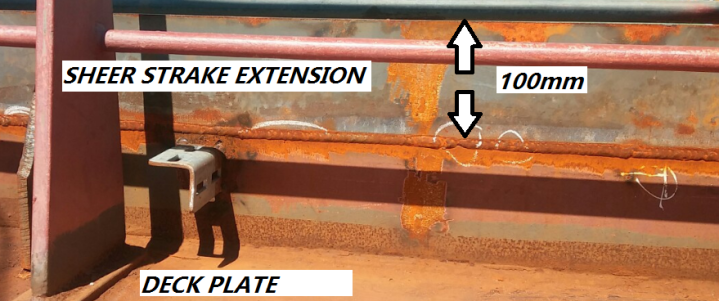

But how about below case as an extension of Sheer strake free edge as owner demand.

I’ll leave this issue as a topic for your notices and may find some more interesting ideas on this matter.

Many thanks, never see something like this before. Good topic!

LikeLike

Great topic. regards

LikeLike

Very important during design/inspection, bros!

LikeLike