『𝐐𝐮𝐞𝐧𝐜𝐡𝐢𝐧𝐠 𝐚𝐬 𝐚 𝐇𝐞𝐚𝐭 𝐓𝐫𝐞𝐚𝐭𝐦𝐞𝐧𝐭』

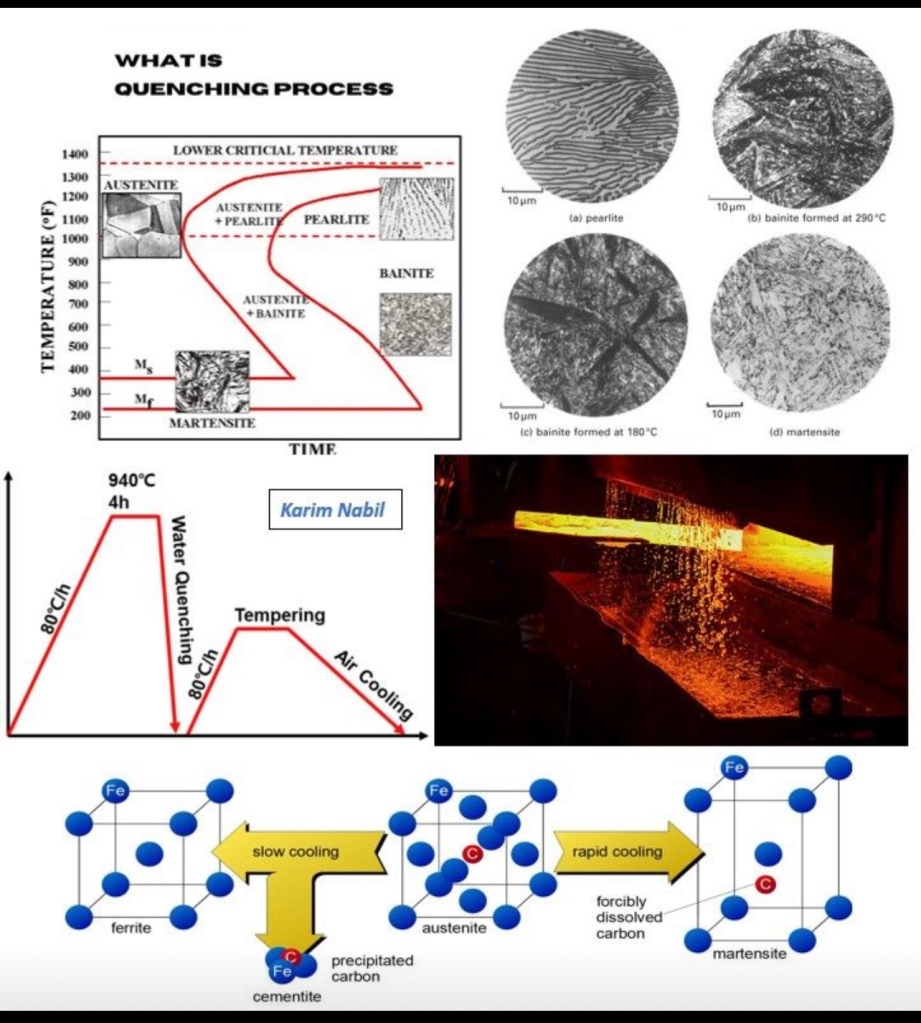

↳𝗤𝘂𝗲𝗻𝗰𝗵𝗶𝗻𝗴 is a vital heat treatment process used to rapidly cool a material, typically a metal alloy, from a high temperature to room temperature or below.

↳𝗠𝗲𝗰𝗵𝗮𝗻𝗶𝘀𝗺 𝗼𝗳 𝗤𝘂𝗲𝗻𝗰𝗵𝗶𝗻𝗴:

1- 𝙃𝙚𝙖𝙩𝙞𝙣𝙜:

The material is heated to a specific temperature, typically above its critical transformation temperature.

2-𝙍𝙖𝙥𝙞𝙙 𝘾𝙤𝙤𝙡𝙞𝙣𝙜 & 𝙋𝙝𝙖𝙨𝙚 𝙏𝙧𝙖𝙣𝙨𝙛𝙤𝙧𝙢𝙖𝙩𝙞𝙤𝙣:

Upon rapid cooling during quenching, the material undergoes a phase transformation depending on the composition of the material.

The most common phase transformation associated with quenching is the formation of 𝙢𝙖𝙧𝙩𝙚𝙣𝙨𝙞𝙩𝙚, a hard and brittle phase characterized by a unique crystal structure (BCT).

↳𝗤𝘂𝗲𝗻𝗰𝗵𝗶𝗻𝗴 𝗠𝗲𝗱𝗶𝘂𝗺𝘀:

Different quenching mediums have varying cooling rates, influencing the resulting microstructure and properties.

1- 𝙊𝙞𝙡:

Provides a moderate cooling rate, resulting in a less severe quench compared to water or polymer solutions.

【It is suitable for materials that require a softer and more ductile microstructure.】

2- 𝙒𝙖𝙩𝙚𝙧:

Offers rapid cooling rates, promoting the formation of a harder microstructure such as martensite.

【It is commonly used for hardening steel alloys.】

3- 𝙋𝙤𝙡𝙮𝙢𝙚𝙧 𝙎𝙤𝙡𝙪𝙩𝙞𝙤𝙣𝙨: ex. Polyvinyl pyrrolidone (PVP)

Provide a controlled and tailored cooling rate.

【Employed for materials that require a balance between hardness and toughness.】

↳𝗣𝗿𝗼𝗽𝗲𝗿𝘁𝗶𝗲𝘀 𝗼𝗳 𝗠𝗮𝘁𝗲𝗿𝗶𝗮𝗹𝘀 𝗮𝗳𝘁𝗲𝗿 𝗤𝘂𝗲𝗻𝗰𝗵𝗶𝗻𝗴:

1- 𝙃𝙖𝙧𝙙𝙣𝙚𝙨𝙨:

Increase the hardness of a material by promoting the formation of a hard phase, such as martensite.

2- 𝙎𝙩𝙧𝙚𝙣𝙜𝙩𝙝:

Enhances the strength of a material, making it more resistant to deformation and yielding.

3- 𝙒𝙚𝙖𝙧 𝙍𝙚𝙨𝙞𝙨𝙩𝙖𝙣𝙘𝙚:

Improved wear resistance due to the increased hardness.

↳𝗗𝗿𝗮𝘄𝗯𝗮𝗰𝗸𝘀 𝗼𝗳 𝗤𝘂𝗲𝗻𝗰𝗵𝗶𝗻𝗴:

One potential drawback of quenching is increased brittleness in some materials, making them prone to cracking or fracture under certain conditions.

↳𝗠𝗶𝘁𝗶𝗴𝗮𝘁𝗶𝗻𝗴 𝘁𝗵𝗲 𝗗𝗿𝗮𝘄𝗯𝗮𝗰𝗸𝘀 𝗼𝗳 𝗤𝘂𝗲𝗻𝗰𝗵𝗶𝗻𝗴:

1- 𝙏𝙚𝙢𝙥𝙚𝙧𝙞𝙣𝙜:

After quenching, reheating material to a lower temperature and then cooling it.

Tempering helps reduce brittleness and improve toughness, while maintaining the desired hardness to some extent.

2- 𝘼𝙡𝙡𝙤𝙮𝙞𝙣𝙜:

Modifying the material’s composition by adding alloying elements can alter its response to quenching.

3- 𝙎𝙚𝙡𝙚𝙘𝙩𝙞𝙫𝙚 𝙌𝙪𝙚𝙣𝙘𝙝𝙞𝙣𝙜:

Instead of uniformly quenching the entire material, selective quenching techniques can be employed to control the cooling rate in specific regions.

Hi,

Nice material. In only confused if it goes about pictures you showed. Because they are signed differently – once “darker” picture is signed martensite (on the graph, to the left), and on the right you signed it bainite.

Which picture is right?

Thanks for answering:)

LikeLike