We will talk about How to tight for bolts of blades after assembly!

Have some method to do it. But in this topic we will say a simple way to do it & not need modern equipment or tools to do. We will use chain locker!

We will take an example for easy understand!

1.Mounting propeller blades:

Blades marked according to above figure , Aft view.

Mounting sequence: 1-3-2-4.

2. Bolt tightening for blade:

– Both pre-tighten and final tighten of the blade bolts with can be done by using socket adapter and ring spanner (a chain block suspended wrench) or hydraulic torque devices, like Hytorc MXT.

– The aft hoisting point at port is used for aft-most blade bolts, the forward hoisting point at starboard is used for forward-most blade bolts.

– If two of these sets are used, the tightening can be done much quicker.

– Use the socket adapter and ring spanner, but lengthen it to 1 meter. Recalculate the pulling force on the dynamometer when the arm length of the wrench differs from 1 meter.

– With a chain block and dynamometer pull over 60 – 90º angle until the tightening torque is reached.

– Pull preferably in one (slow) pull. Do not pull intermittently. Read the torque when the angle between wrench and dynamometer is 90º.

- Mounting sequence:

- Torque valuse: take sample

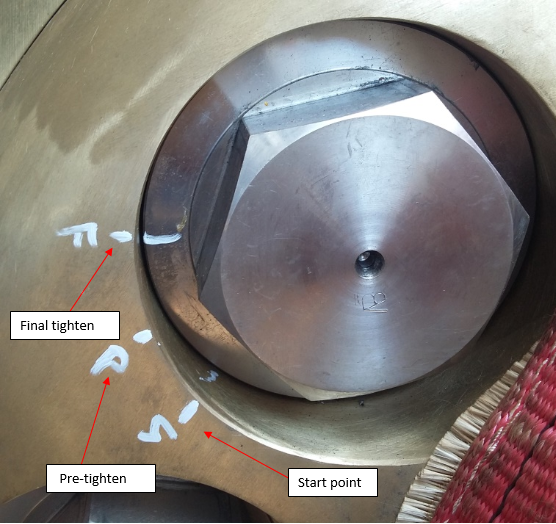

It has 2 steps: pre-tighten 700Nm & final tighten 12200Nm.

- The angle when read the torque value is very importance.

- The angle to be 90 degree if not we need calculate for other angle:

3. Leak test to confirm no leaking after bolt tighten. This item check leaking at blade & hub of propeller also.

4. Secure the bolt:

5. Summary:

When mounting or demounting propeller blades, follow the rules listed below:

● Take care for controlled hub rotation, especially when not all blades are attached to the

hub.

● When demounting, decide on the number of blades to be de-mounted.

● Carry out grinding or welding on locking strips in one action on all blades.

● Tighten or loosen all blade bolts in one action on all blades.

● Place demounted propeller blades in lying position on wooden pallets. This to avoid falling over caused by the centre of gravity of the blade.

● Collect spilled oil in catch tanks.

Very nice topic with high quality images.

LikeLiked by 1 person

Hi, I was hoping you could give me some assistance. I am from the vessel Gema and we are replacing a blade seal on a Ulstein CPP. The manual says to preload the bolts 5.5 (or 55, its a 30 year old manual) degrees with a chord lenght of 60mm.

I am not so sure what they mean with this, any chance you have some advice?

LikeLike