CSWIP 3.1 QUESTION AND ANSWER SERIES

[BUY] CSWIP 3.1 Learning Package

(145mb) Books & Chapter wise Questions (General Paper + Technical Paper) and Answers. Examination notes on Practical Examination of Plate/Pipe CSWIP 3.1 Learning Presentation

$72.00

CSWIP 3.1: Question with Answer and Explanation – Part 3

1) Why is it essential to clean the excess weld metal on completion of the production weld?

| a. | So it can be ready for painting |

| b. | To remove any rust |

| c. ( answer ) | To ensure it is suitably clean for visual inspection and NDT |

| d. | To remove slag from the undercut |

After production weld finished. The surface to be examined shall be free from all dirt, grease, lint, oil, scale or slag. If it needs do NDT, the excess weld metal to be cleaned suitably for NDT.

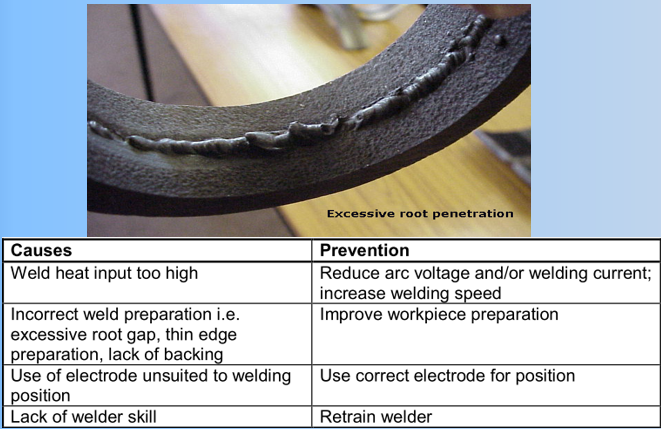

2) During root welding, which of the following would be the main cause of excess penetration?

| a. | The root gap is too small in accordance with WPS |

| b. | Preheat not used |

| c. ( answer ) | The current is too high |

| d. | Root face is too large |

Arc energy (kJ/mm)= (Volts x Amps) / (welding speed(mm/s) x 1000). It means Amps high –> HEAT INPUT high –> excess root penetration.

3) At what level is H2 considered to be more critical in cracking?

| a. | Less than 5ml per 100g of weld metal deposited |

| b. | Between 5 and 10ml per 100g of weld metal deposited |

| c. | Between 10 and 15ml per 100g of weld metal deposited |

| d. ( answer ) | Over 15ml per 100g of weld metal deposited |

4) With regards to Lamellar tearing, a buttering layer will:

| a. ( answer ) | Improve ductility |

| b. | Disperse heat |

| c. | Improve toughness |

| d. | Improve hardness |

Lamellar tearing occurs when material have Susceptible Microstructure – Poor through thickness ductility.

The surface of the fracture is fibrous and ‘woody’ with long parallel sections which are indicative of low parent metal ductility in the through-thickness direction.

a) Buttering the surface of the susceptible plate with a low strength weld metal has been widely employed. As shown for the example of a T butt weld (Fig. 5) the surface of the plate may be grooved so that the buttered layer will extend 15 to 25mm beyond each weld toe and be about 5 to 10mm thick.

b) In-situ buttering ie where the low strength weld metal is deposited first on the susceptible plate before filling the joint, has also been successfully applied. However, before adopting either buttering technique, design calculations should be carried out to ensure that the overall weld strength will be acceptable.

Note: Steel suppliers can provide plate which has been through-thickness tested with a guaranteed STRA value of over 20%.

5) Lamellar tearing can be detected by which of the following NDE methods?

| a. | Radiography |

| b. ( answer ) | Ultrasonics |

| c. | Eddy current |

| d. | MPI using AC |

If surface-breaking, lamellar tears can be readily detected using visual examination, liquid penetrant or magnetic particle testing techniques. Internal cracks require ultrasonic examination techniques but there may be problems in distinguishing / identify lamellar tears from / with inclusion bands. The orientation of the tears normally makes them almost impossible to detect by radiography.

6) A fatigue fracture can be identified (from examination of the fracture …):

| a. ( answer ) | The presence of beach marks |

| b. | The presence of plastic deformation |

| c. | Being rough and torn |

| d. | Being flat and rough |

The surface is smooth and shows concentric rings, known as beach marks, that radiate from the origin; these beach marks becoming coarser as the crack propagation rate increases. Viewing the surface on a scanning electron microscope at high magnification shows each cycle of stress causes a single ripple. The component finally fails by a ductile or brittle overload.

7) A steel designated as “Z” quality will have:

| a. ( answer ) | Through thickness ductility > 20% |

| b. | Through thickness ductility < 20% |

| c. | Been specially heat treated |

| d. | Zirconium added to improve weldability |

Note: Steel suppliers can provide plate which has been through-thickness tested with a guaranteed STRA value of over 20%.

Two main options are available to control the problem in welded joint liable to lamellar tearing:

-Use clean steel with guarantee through-thickness properties (Z grade)

-A combination of joint design, restraint control and welding sequence to minimize the risk of cracking

8) Which of the following types of destructive test is sometimes used for welder qualification testing:

| a. | Hardness test |

| b. ( answer ) | Fracture test |

| c. | Charpy V notch impact test |

| d. | CTOD test |

- We need to know what is Fracture test?

- Welder qualification – BS EN 287: the fracture test to be done for welder qualification as below table.

9) Which one of these tests would most probably be used for welder qualificaiton on a plate butt weld using 13mm low carbon steel:

| a. | CTOD |

| b. ( answer ) | Nick break test |

| c. | Fracture fillet test |

| d. | IZOD |

- Pls take note this question apply for welder.

- CTOD – Crack Tip Open Displacement: To determine the fracture toughness or resistance towards crack extension.

- Nick break test: To permit evaluation of any weld defects across the fracture surface of a butt weld. This is righ answer for above question.

- Fracture fillet test: To break open the joint through the weld to permit examination of the fracture surfaces ( fillet weld ). See previous question.

- IZOD: Izod Impact Test:

10) A transverse tensile test piece from a weld joint will give the:

| a. | Tensile strength of the weld |

| b. | Tensile strength of the joint |

| c. | Stress/Strain characteristics of the weld |

| d. ( answer ) | Stress/Strain characteristics of the joint |

Transverse Tensile Tests: To measure the transverse tensile strength of a butt joint under a static load.

Pls see next part: part 3

One thought on “CSWIP 3.1: Question with Answer and Explanation – Part 2”