- Cold Corrosion

- Hot Corrosion

Cold Corrosion :

JACKET WATER TEMP TOO LOW/ “EEDI” COMPILATION –> COLD CYLINDER

COLD –> VAPOUR FORM + SOx –>ACID –> CORROSION

- Cold corrosion can be caused by low exhaust temperatures during very low load operations. Care should be taken to avoid exhaust temperature after the cylinder to drop below 250 deg C. This figure is particularly important as temperature will drop further after extraction of heat in the exhaust boiler.

- It’s low temperature corrosion

- Due to sulphur and sulphur products

- Source : Fuel oil contains sulphur

- Occurs in lower part of Liner, generally (lowest temp’ part caused of air inlet and exhaust gas release stage)

- Comply with NOx regulations and EEDI (energy efficiency design index) – caused of In compliance with Tier II NOx regulations and Energy Efficiency Design Index (EEDI) guidelines, engine cylinders must operate under increased pressures and reduced operating temperatures. These regulations have led to an increase in cold corrosion. The increased pressure and reduced temperatures within the engine cylinder create conditions below the dew point, allowing water to condense on the cylinder liner walls. That condensate combines with sulphur, forming sulphuric acid – corroding the liner surface and creating excessive wear of the liner material.

- During Maneuvering, it will be more dangerous

- Serious problem with latest design.

Explanation:

- Fuel contains sulphur products and water.

- In combustion, SOx is formed (after burning of sulphur products, oxides are formed).

- In lower part of cylinder liner, water vapour is present due to cooling system.

- Water vapours and SOx are mixed or combined and forms Acid.

- If dew point for vapour is attained then condensation occurs and hence formation of liquid drops. (Cold corrosion is the most serious in modern engine designs and earlier engine designs that have been modified for part-load or low-load operation (known as “slow steaming” where vessels may operate as low as 10 percent load).

- Below dew point of acid, it becomes very corrosive.

EEDI modification

- Turbocharger cut-out

GOOD: for saving cost, fuel up to 50% at low speed operation (low steaming mode)

BAD: Reduce pressure in scavenger –> air colder –> cold corrosion

- Variable turbo charger nozzle rings fitted (VGT type)

GOOD: increase pressure for boosting the turbocharge (by nearly closed nozzle) –> high saving at low load condition.

- Exhaust gas bypass valve fitted

GOOD: to avoid overload in main engine because of high pressure and high density.

- Engine tuning changes

GOOD: fuel injection sequence, spark sequence optimized –> more saving cost.

The other reason by over-addicted oil lubricate due to the High feeding rate for the low sulfur-fuel running condition. See the SOx control chapter.

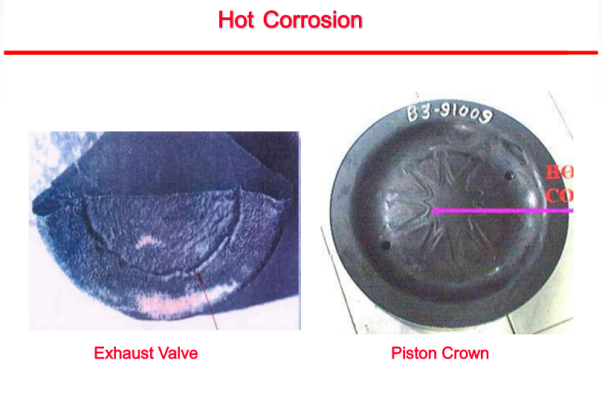

Hot Corrosion :

- Due to High Temperature, High temperature corrosion

- Sodium and Vanadium compounds are formed at high temperature which plays crucial role in hot corrosion

- After 600 degree, rate of corrosion will be very high

- Fuel contains vanadium compounds

- Vanadium oxides and tri-oxides do not promote corrosion

- (Na2O . 6V2O5 ) have highest Corrosion rates at temperature above 600 degree

- More effective than Cold corrosion.

Explanation:

- Fuel contains Vanadium compounds, which can form low melting compounds at high temperature, these are highly corrosive.

- During solidification of Na-V compounds, releases molecular oxygen which can attempt the metal surface, which causes oxidation and hence corrosion.

Affected Parts : Exhaust valve, Piston crown, Turbocharger components, liner is less affected by it.

- Na2O.6 V2O5 have the highest corrosion rates at the temperatures between 593 °C and 816 °C.

- The presence of sodium in a ratio of 1:3 gives the lowest melting point and must be avoided.

- Use fuel with Na-V ratio outside the critical zone.

- Ensure efficient oil purification.

- Keep mean exhaust temperature below 500 degree and inlet temperature below 530 degree.

- Ensure that demisters are working properly.

Our dedicated accounts team handle everything to ensure you get gas delivered straight to your vessel as and when you need it. We take away the stress of procuring calibration/span and quad gas, as well as work towards saving you more than 50% on your gas administration costs.

LikeLike