1-WHY DO SHIPS HAVE ICE CLASS?

- To permit the safe operation of ships in ice-covered sea areas

Visit: Shipbuilding Knowledge A-Z for more free topics on shipbuilding

2-WHO REQUIRE ICE CLASS QUALIFICATION?

- Coastal states with seasonal or year-round ice-covered oceans and seas

Specific oceans and sea areas in the context of current and earlier commercial shipping developments for ice operation as well as applicable ice classes:

BALTIC SEA:

- Bay and Gulf of Bothnia, Gulf of Finland – Finnish-Swedish Ice Class Rules (FSICR)

- Gulf of Finland (Russia territorial waters) – Russian Maritime Register (RMR) Ice Class Rules

ARCTIC OCEAN:

- Barents, Kara, Laptev, East Siberian and Chukchi Seas – Russian Maritime Register (RMR) Ice Class Rules

- Beaufort Sea, Baffin Bay, etc – Canadian Arctic Shipping Pollution Prevention Rules (CASPPR)

OKHOTSK SEA:

- Russian Maritime Register (RMR) Ice Class Rules

There are also ice class rules and regulations for commercial ship operations on inland lakes e.g. the Great Lakes …

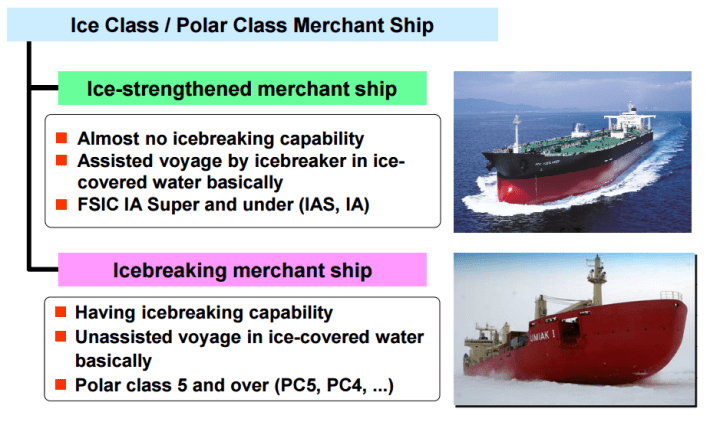

3-HOW MANY TYPE OF ICE CLASS

The ice class designations and requirements applied by the different classification societies may sometimes be different from each other. Thus, when ordering a 1A Super

newbuilding you may have:

-Finnish-Swedish rules : 5 knots in 1.0 m brash ice with 0.1 m frozen top layer

-Lloyd’s Register: 5 knots in 0.3 m solid ice with snow on top

-American Bureau of Shipping: Only brash ice

-Det Norske Veritas: Ship specific.

4-WHAT IS ICE CLASS COUNT TOWARD SHIP DESIGN

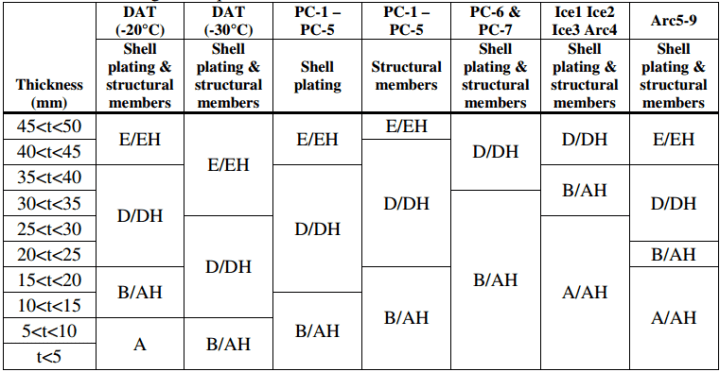

- STRUCTURE INTEGRITY (THICKNESS, GRADE)

DAT: Design-ambient air temperature for structural material

LIWL Lower Ice Waterline

UIWL Upper Ice Waterline

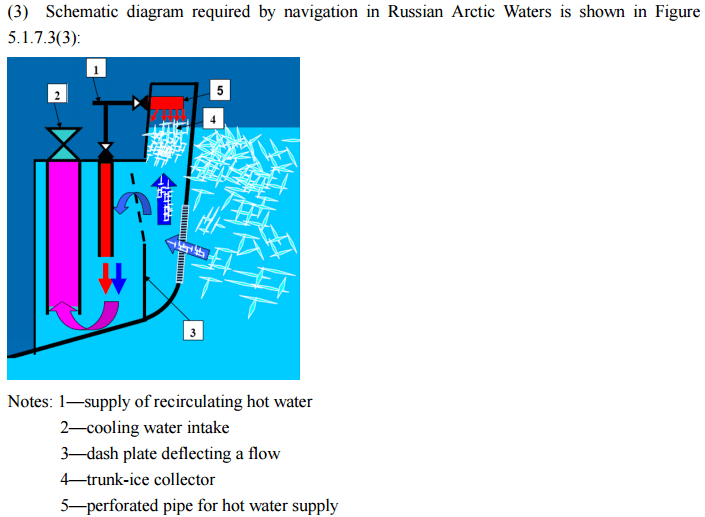

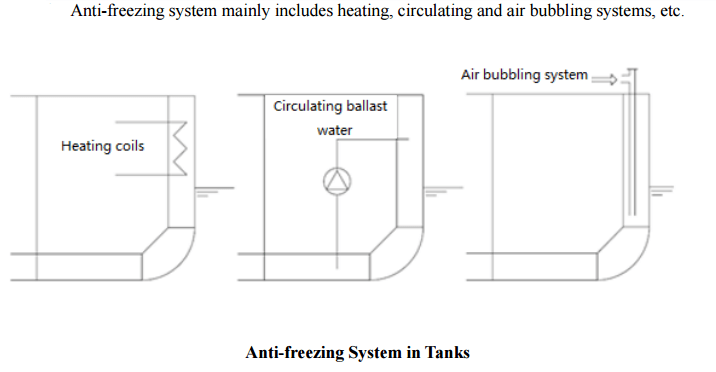

- BALLASTING, PROPULSION AND M/E SAFETY OPERATION

In order to protect the engine against cold corrosion attacks on the cylinder liners, some minimum temperature restrictions (Keep Jacket Cooling Water at optimum temperature of about 80 to 85 deg C and avoid fluctuations. Keep at the highest temperature permitted by the engine manufacturer. This helps to reduce the thermal stresses on the liner and avoid cold corrosion ) and load-up procedures have to be considered before starting the engine.

See mean of cold corrosion attacks in Machinery category

Note: the cold air has more density the compression pressure and the maximum firing pressure will be too high –> leading to overload.

2 thoughts on “SHIP ICE CLASS”