Ships need ballast water for many reasons:

- To achieve the sufficient draft and stability

- To reduce stress on structure integrity

- To correct the list or trim

Ships carry ballast water to maintain stability in rough seas and when sailing without cargo. After a vessel has been unloaded the water is typically pumped into purpose-built tanks onboard. It is then drained during loading at the destination port, bringing ashore organisms which pose environmental and even health risks. This is suspected to have contributed toward a cholera outbreak in Peru – bệnh dịch tả hoành hành tại Peru that affected over 10,000 people.

The International Convention for the Control and Management of Ships’ Ballast Water and Sediments aims to find a solution to the issue. The International Maritime Organization (IMO) introduced the accord in 2004, obliging shipowners to treat or safely replace their ballast water. The requirement is that reduces the amount of living invasive species released into coastal and harbor waters.

To Deal with D-1 standard, what is involved in Ballast Water Exchange (BWE)?

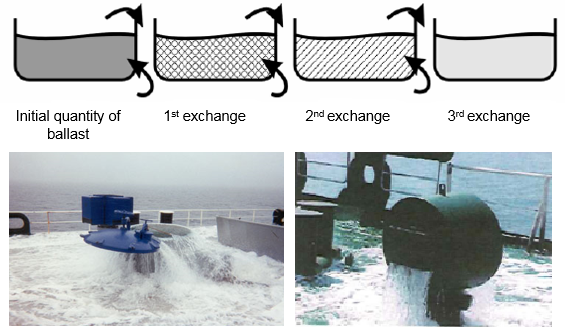

The process of ballast water exchange involves the substitution of the water in the vessel’s ballast tanks using one of the following methods:

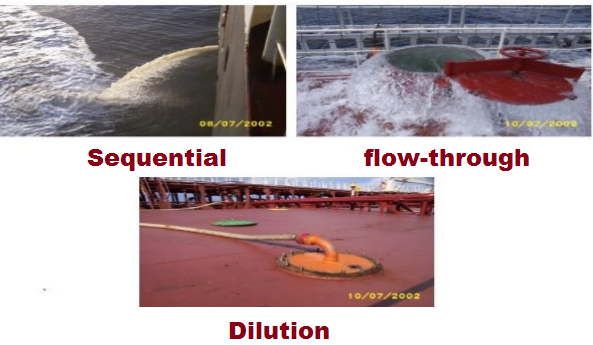

• Sequential method : after departure with ballast condition, each ballast is emptied to 75-95% and refilled with deep-ocean water.

• Flow-through method : pumping to overflow

• Dilution method: ballasts filled through the top allowing discharge from the bottom

The IMO requirements state that any exchange procedures must be carried out, whenever possible, at least 200 nautical miles from the nearest land, and in water at least 200 metres in depth. Where that is not possible, the procedures must be at least 50 nautical miles from the nearest land, and, again, in water at least 200 metres in depth.

BWE Disadvantages:

Its implementation gives rise to a number of practical problems

- The operation is laborious – man power and equipment much spent.

- The sequence may endanger the strength of the structure (particularly on vessels which are sensitive to longitudinal strength – such as tankers and bulk carriers. In addition to this, the procedures could result in slack water within the tanks, with additional free surface moment impacting the vessel’s dynamic stability)

- Needs favorable sea and swell – wave conditions,…

Three Reasons Why BWE May Not Be Appropriate For All Vessels

- The vessel’s ballast pumping and piping arrangement, and approved loading conditions may hinder or prohibit performing open-sea exchange.

- The vessel may not be able to conduct exchange because the route has insufficient distance or water depth.

- Conducting exchange depends upon favorable weather and sea surface conditions.

Due to limited biological efficiency the Exchange Standard (D‐1) is to be regarded as an interim measure. Upon entry into force of the convention, the ballast water exchange method would be phased out and a type approved “Ballast Water Management System” – BWMS D-2 standard have to be installed onboard.

Regulation D-2 of the Ballast Water Convention sets the standard that ballast water treatment systems must meet . Treatment systems must be tested and approved in accordance with the relevant IMO Guidelines.

A brief description of current BWMS Technology complying with D-2 as below:

Ballast water is treated using the complete process during ballast water intake and

re-treated during ballast water discharge through the UV reactor only (filter bypassed during discharge). Re-treatment during discharge is necessary to eliminate possible re-growth of bacteria in ballast tanks due to cross contamination or incomplete intake disinfection.

All ships will be required to have an approved Ballast Water Management Plan on board and a Ballast Water Record Book. All ships of 400 gross tonnes (gt) and above must also be surveyed and issued with an International Ballast Water Management Certificate or a Ballast Water Management Certificate of Compliance.

All ships will be required to have an approved Ballast Water Management Plan on board and a Ballast Water Record Book. All ships of 400 gross tonnes (gt) and above must also be surveyed and issued with an International Ballast Water Management Certificate or a Ballast Water Management Certificate of Compliance.

Although the IMO MEPC- has recently agreed to delay the deadline for some vessels to retrofit ballast water treatment systems, certain requirements of the Ballast Water Management Convention must still be complied with by 8 September 2017.

Prepare for 8 September 2017

Members and clients are reminded that the BWM Convention applies to almost all vessels in international trade using ballast water, including submersibles, floating craft, floating platforms, FSUs and FPSOs, and that, after 8 September 2017, such vessels must:

- have an approved BWM Plan onboard (regulation B-1);

- maintain a ballast water record book (regulation B-2);

- for a vessel of 400 gross tonnes and above, be surveyed and issued with an international ballast water management certificate (regulations E-1/E-2);

- assign a competent officer to manage ballast water and to train officers and crew so that they can carry out their respective duties; and

- manage their ballast water on every voyage, either by performing ballast water exchange (regulations B-4/D-1) or by operating an approved ballast water treatment system (regulations B-3/D-2).

on or after September 8, 2017

What is the IOPP?

The IOPP certificate is issued to each new ship after an appointed surveyor has inspected it and found it to be in compliance with the MARPOL convention. The IOPP certificate gives details of all oily water separation and filtering equipment and also the associated monitoring equipment required under the convention.

The Oil Pollution Prevention (Annex 1) covers a wider scope at present. If all the requirements are complied with, the certificates and survey intervals are detailed as follows:

|

Name of Certificate

|

Survey Interval

|

| International Oil Pollution Prevention Certificate (IOPP) | Renewal Survey: Carried out every 5 years. |

| Intermediate Survey: Carried out within 3 months before or after the second or third anniversary date in replacement of one required annual survey. | |

| Annual Survey: Carried out within 3 months either way of each anniversary date. |

2 thoughts on “Ballast Water Management System”