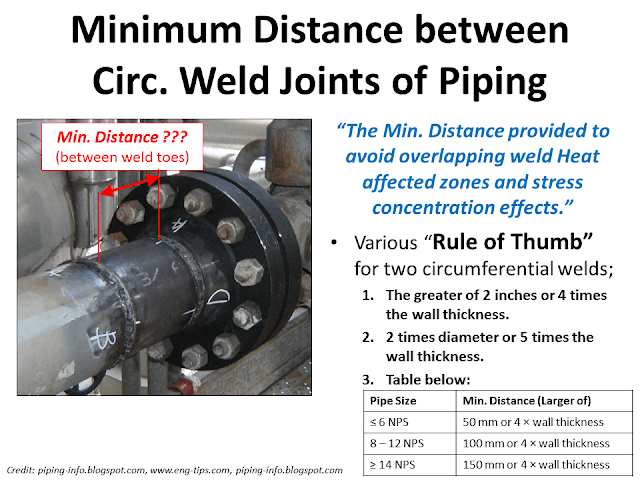

Purpose of Welding proximity requirement is:

1 – To avoid the overlapping HAZ, the lowering of the welding HAZ mechanical properties which is not covered in WPS is approved for welding configuration.

2- To avoid the duplicate of residual stress between two joints which may combine with the load during service, this leads to structural failure due to the total combined local stress exceeding allowable stress.

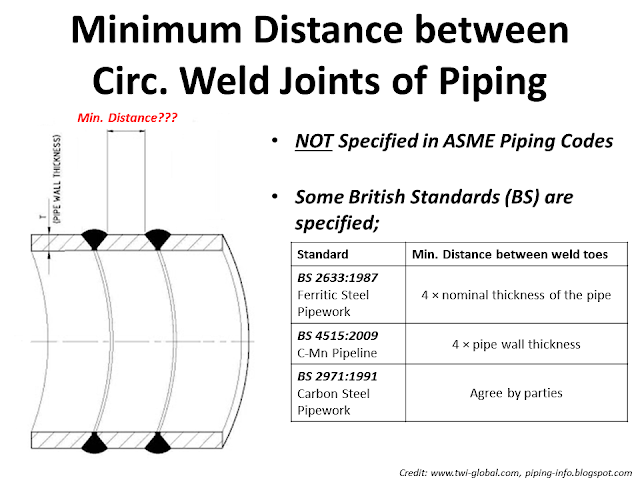

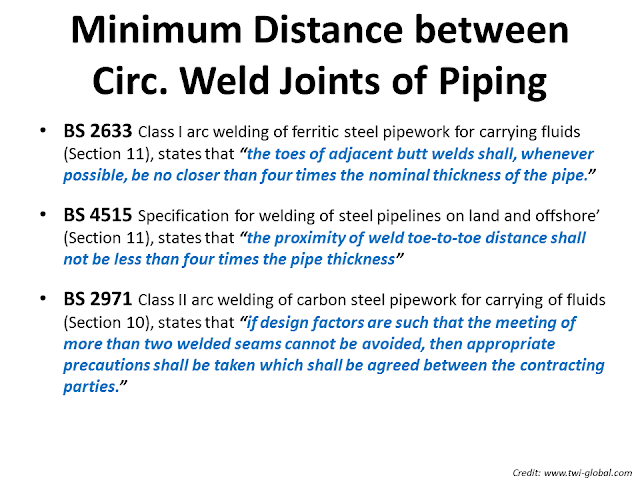

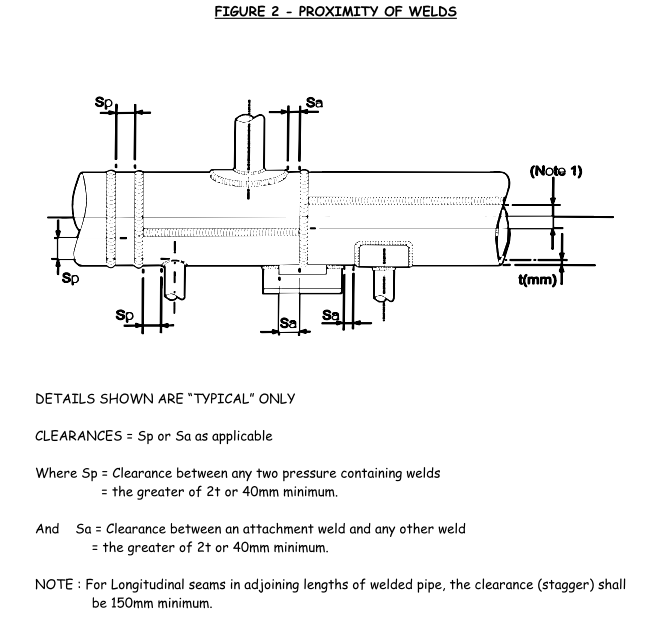

Weld proximity is covered by a number of international standards. Extracts from these standards are shown below and summarized in the following table:

| Standard | Applies to | The minimum distance between weld toes | Notes |

| BS 2633:1987 | Ferritic steel pipework | 4t | t= nominal thickness of the pipe See below for notes on attachment welds. |

| BS 4515:2009 | C-Mn pipelines | 4t | t= pipe thickness |

| BS 2971:1991 | Carbon steel pipework | Agreed by parties | – |

| PD 5500:2012 | Pressure vessels | 4e or 100mm whichever is greater | e= design thickness Refers to the staggering of longitudinal welds |

| ASME B&PV | Boilers and pressure vessels | Not specified | – |

A B31.1 Interpretation says

Interpretation: B31.1-22-7

Subject: B31.1, 127.4, Welding Requirements

Date Issued: December 10, 1992

File: B31-92-027

Question: Does the B31.1 Code require that a minimum distance be maintained between adjacent piping welds.

Reply: No. However, refer to paragraph 104.3.1(G.7) for rules regarding the reinforcement of multiple openings.

A B31.3 Interpretation Says

Interpretation: B31.3-7-02

Subject: B31.3-1987, Paras. 304.3.3 and 328; Spacing of Welds

Date Issued: May 24, 1988

File: B31-87-039

Question: In accordance with B31.3, are there requirements or guidelines on the minimum distance between welds in a pipe?

Reply: No, except as provided in paragraph 304.3.3(e).

Para 304.3.3(e)refers to the overlapping of reinforcement zones.

In the oil and gas project, the code normally not requires about this issue, but it’s necessary to notify in the project’s Specification on welding & inspection.

Example:

Because of the HAZ overlapping, thus the weld-zone mechanical will be affected with no support documents that proving the soundness of weld especially in welding DSS – high corrosion material (weld decay).

Because of the design capability and actual narrow arrangement, this issue can’t be avoided 100%. In such a case, a Technical query has to be issued and supported by a production test. (Hardness test is normally to be presented for closing this issue).

is there any literature on the effects of overlapping HAZ?

LikeLike

The effect of overlapping HAZ zone will be an interesting topic will be posted later. Btw, the Heat range from 700*C to 1300*C will be devided to 3 to 4 type of affections which is may increase the strength or decrease the corrosion resistance, depending on the material susceptibility and appication.

LikeLike

any more literature for weld in vicinity

LikeLike

Please share your concerns, someone will help you.

LikeLike

Most industrial codes put restrictions on weld proximity or intersection during fabrication of steel structure. However no technical justifications has been given in the literature and industry codes for the restrictions imposed on weld-on-weld or welds in proximity.

Sometimes at the fabrication stage there are circumstances by which the weld over an existing weld or in a close proximity is not avoidable.

weld-on-weld joints are identified during inspections sometimes in the service life of the asset.

In such scenarios the ability to achieve code compliance and make an informed decision for the appropriate course of action is of prime importance.

share your views on same

LikeLiked by 1 person

In my concern, the welding proximity should be avoided at cyclic loading structure joints. The residual stress at too closed welding joints may by balanced or duplicated by the resonant effect which can cause unpredict cracking during service.

LikeLike