Holiday Test – Overview;

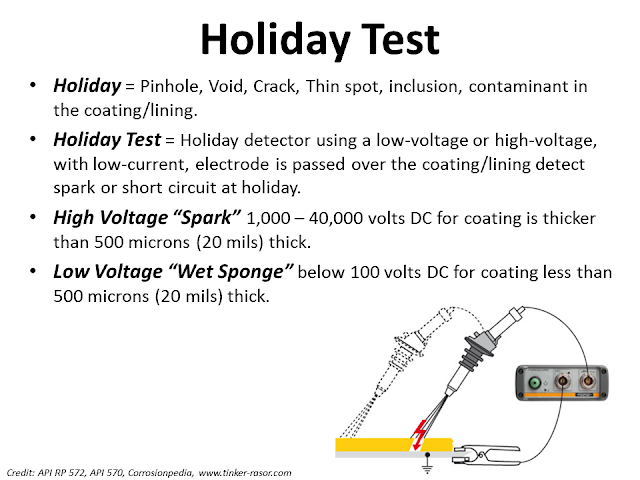

A holiday test here refers to defects in coating or lining, which are Pinhole, Void, Crack, Thin Spot or Contaminant. Holiday Test is a method for checking these defects by providing electricity through the defects in Coating/lining to Workpiece. If any area has a defect, spark or short circuit will occur. Holiday Test will be divided into two(2) main methods. According to the thickness of Coating/lining by Low Voltage or “Wet Sponge”

It applies to Coat thickness less than 500 microns of High Voltage or “Spark” is used to Coating thickness greater than 500 microns.

Example of understanding the methods:

Low Voltage Holiday Test – Example of Internal Coating of Heat Exchanger Channel;

Examples of doing Low Voltage Holiday Test or Wet Sponge Test with Internal Coating / Painting of Heat Exchanger Channel to prevent corrosion from Cooling Water Service. To do a Holiday Test is to check the quality of Coating / Painting by Electrodes used as a wet sponge “

*** For High Voltage “Spark” Holiday Test:

High Voltage Holiday Test – Example of Rubber Lining;

Examples of doing a High Voltage Holiday Test or “Spark” Test with Rubber Lining within Pressure Vessel (HCl Storage Vessel) to check for defects and deterioration of Lining that may occur during the use of Vessel.

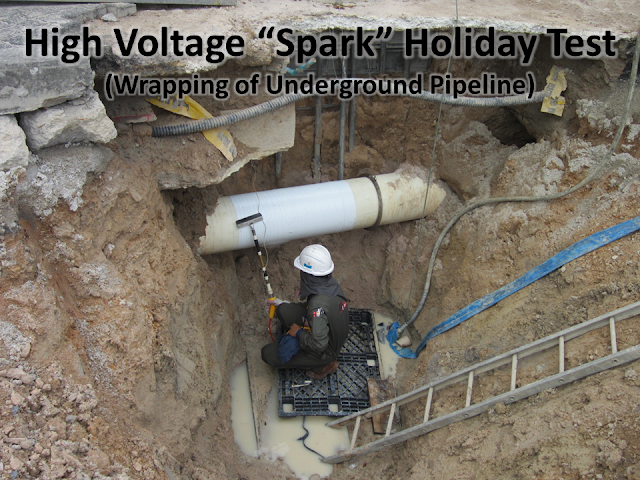

High Voltage Holiday Test – Example of Wrapping Repaired Section of Underground Pipeline;

Example of High Voltage Holiday Test or Spark Test against Wrapping of pipe underground (Underground, Pipeline) in the Repair and Wrapping to check the quality of Wrapping by Electrodes are used both a brush and a hoop around.