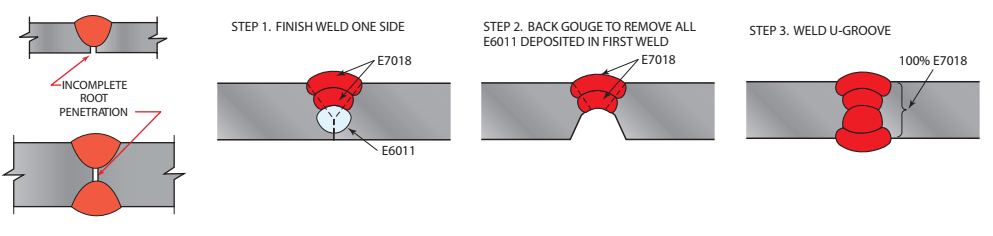

In general, butt joint welding is divided into two-sided welding welded on both sides and the back gouging must be applied due to poor welding quality at the first welding layer of the first one-sided welding. (Call completed joint penetration, See What is CJP in welding)

For one-side welding method, a backing material, which is a backing material that prevents melting of molten metal, is attached to the backside of the base material, and then the welding wire is lowered to form an arc between the base material to weld the base material.

Welded Chill Plate (or Permanent backing strip, steel backing) is applied for full penetration welding of one side with butt joint improvement groove in the place where the backside of steel structure made of large blocks such as ship, offshore structure, steel bridge, cofferdams, is difficult to access or up-side-down the structure for welding the second side.

In the conventional welding backing material 2, as shown in FIG. 1, a thin and narrow steel plate of the same material as that of the base material 1, 1a is installed in the welding line direction. Otherwise, in the closed space, even after the welding is completed, the backing material is left without being removed.