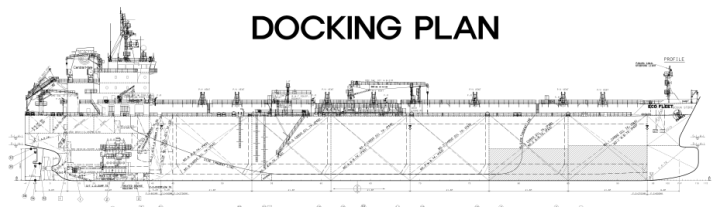

Docking Plans:

A docking plan is a document that is prepared for every ship during its preliminary design phase. All the information required to bring a ship to a dry dock is included in its docking plan. While most of the information is condensed into drawings, one must also refer to the textual references and notes provided, because they also inform us about the type of dry dock that is being used and technical specifications of dry dock that should be met before the ship is docked.

Visit: Shipbuilding Knowledge A-Z for more understanding shipbuilding.

The contents of a typical docking plan are discussed below:

- Table of Hydrostatics and Hydrostatic Curves:

The first few hydrostatics that must be checked before a ship enters a dry dock are:

- Forward draft.

- Aft draft.

- Longitudinal Center of Buoyancy.

- Moment to Change Trim by 1cm. (MTCT)

- Center of Gravity.

- Longitudinal Center of Floatation.

- Transverse metacenter.

Since it is not preferred to provide the information in an easily obtainable manner, a tabular form of hydrostatic data is more preferable than the curves. In the case of intermediate values, interpolation methods are used and then tallied with the curves.

Docking Surveys – Class Rule Requirements

At Docking Surveys or In-water Surveys the Surveyor is to examine the ship and machinery, so far as necessary and practicable, in order to be satisfied as to the general condition.

For oil tankers (including ore/oil and ore/bulk/oil ships), chemical tankers and bulk carriers over 15 years of age the intermediate docking between Special Surveys are to be held in dry-dock. Further, this survey is to be held as part of the Intermediate Survey.

Where a ship is in dry-dock or on a slipway it is to be placed on blocks of sufficient height, and proper staging is to be erected as may be necessary, for the examination of the shell including bottom and bow plating, keel, stern, stern frame and rudder. The rudder is to be lifted for the examination of the pintles if considered necessary by the Surveyor.

Dock Sill Height

There is one more reason for reducing the docking draft of the vessel and that is the ‘sill height’ of the dry dock. Although the depth of water in the channel may be sufficient to accept vessels of a certain draft, the sill height at the entrance of the dock may be insufficient to allow this draft. Due to this reason, the vessel is docked when the depth of water near the dock entrance is maximum, which condition exists during the high tide only. Thus docking and un-docking dates have to be planned after taking into consideration the tidal variations at the place where the dry-dock is situated.

What are Keel Blocks?

This facility of adjusting the height is necessary because the ship’s bottom plate may not be exactly in a straight line (even a few millimeters of difference can result in overloading the hull structure and deforming the same and all classification rules allow certain tolerance in the straightness of the keel) and blocks of the same height can result in some portion of the hull not touching the blocks below that. This will, in turn, load the adjacent blocks which are touching the hull.

To learn more detail in full detailed DWG of SHIP DOCKING PLAN. Please contact for purchasing the high-quality product (PDF format).

One thought on “SHIP DOCKING PLAN”