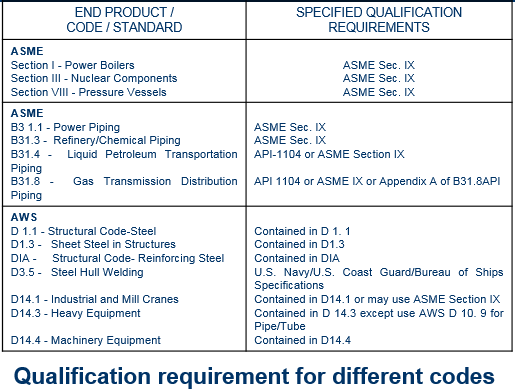

First glances of Welding Codes Application:

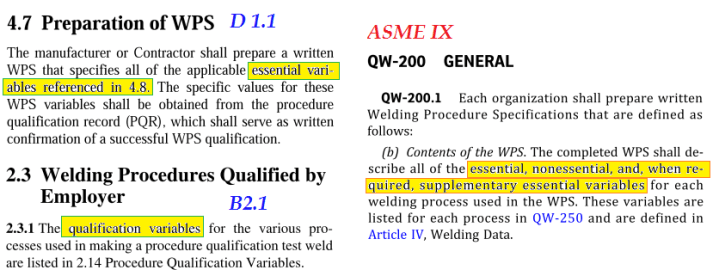

Initial Concepts of Variables:

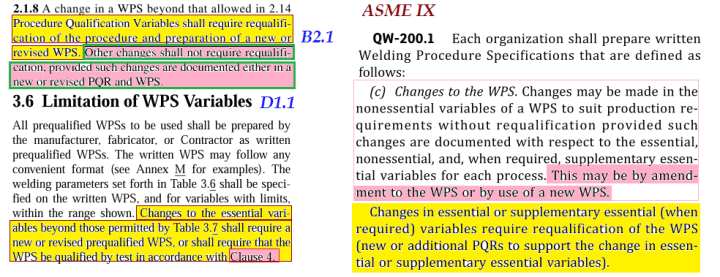

The Changes of Variables affecting to WPS qualification status:

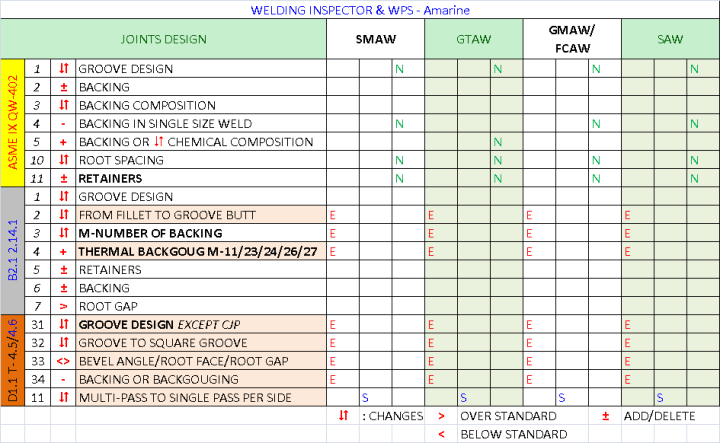

KEY NOTES:

* Groove changes mean : U —> V, J —> V, X —> V ect., (excluded the T-Y-K Jacket joints)

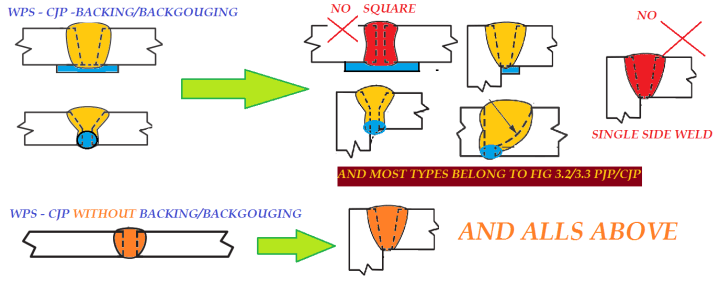

* CJP groove mean of using Backing/Backgouging

* Groove weld is different with Fillet weld (Weld type including Groove & Fillet)

WPS with Groove type can cover the Fillet, but Fillet WPS can cover only Fillet weld

ASME IX FILLET JOINT QUALIFICATION

B2.1 FILLET JOINT QUALIFICATION

D1.1 FILLET JOINT QUALIFICATION

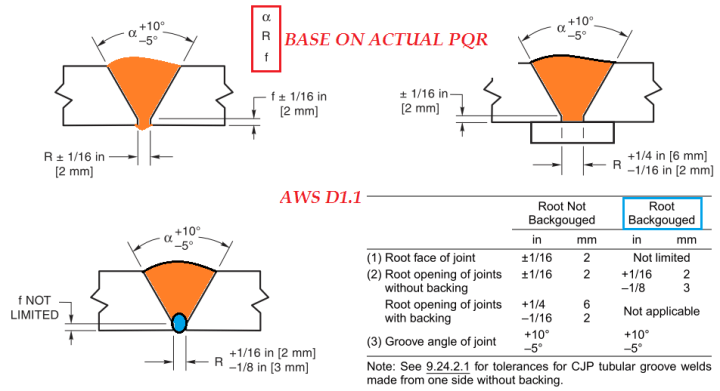

* ONLY FOR AWS D1.1 (33) – ROOT FACE/GAP,BEVEL ANGEL Not that the others joint design change like Excessive Root Gap (>5mm – backing ,>8mm – buildup or increase leg size ect.,) is relating to Practical correcting solutions to matching the WPS designate, NOT to Re-qualify the WPS.

Not that the others joint design change like Excessive Root Gap (>5mm – backing ,>8mm – buildup or increase leg size ect.,) is relating to Practical correcting solutions to matching the WPS designate, NOT to Re-qualify the WPS.

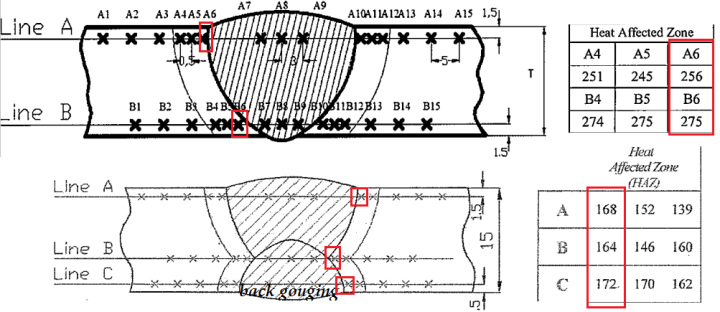

BUT HOW ABOUT ASME IX WPS FOR BELOW CASE:

Solutions:

1 – REVISING WPS (IN CASE OF SERIOUS CONCEPTS: HARDNESS/CORROSION/IMPACT)

2 – TECHNICAL QUERY OR MOCK-UP TEST TO BE PRESENT (IN CASE OF SERIOUS CONCEPTS: HARDNESS/CORROSION-NACE COMPLIANCE/IMPACT/FN CONTENT).

Duplex SS is susceptible to embrittlement Heat temp’ (600-800*C) which relating to metallurgy aspect and will be discussed in Metallurgy topic.

One thought on “Welding Inspector & WPS (PART 1)”